Design Method and How it Affects the Cost, Weight and Lifetime of the Project

Design Method and How it Affects the Cost, Weight, and…

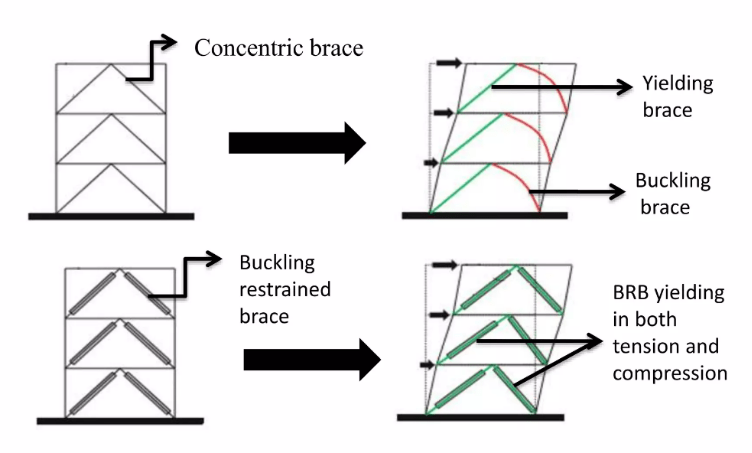

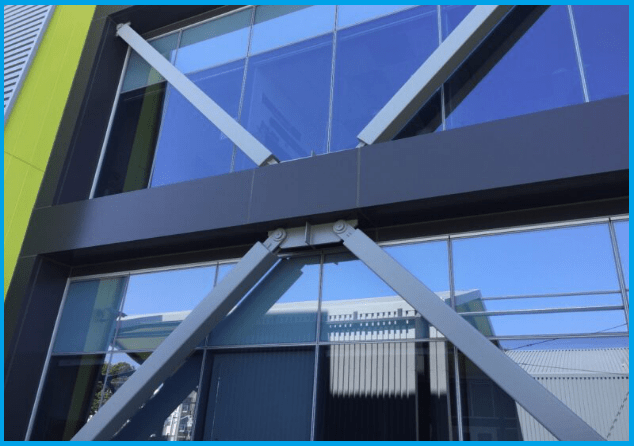

The brace that attempts to inhibit buckling under compression is called BRB (Buckling Restrained Brace). A BRB allows the building to withstand cyclic lateral loading, typically earthquake-induced. A BRB can yield both in tension and compression without buckling.

A Normal Brace under loading has several disadvantages

A BRB eliminates all these disadvantages.

The concept of BRBs was developed in Japan by Nippon Steel at the end of the 1980s and was known by its trademark name of Unbonded Brace.

It was first installed in the United States in 1999, in the Plant & Environmental Sciences Building in U.C. Davis. In 2002, both CoreBrace LLC and Star Seismic LLC were incorporated, and began competition with Nippon in the BRB design market.

BRB usage is currently accepted, with its design regulated in current standards, throughout the world.

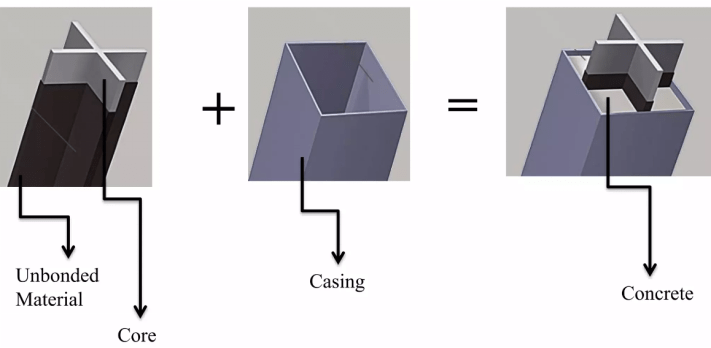

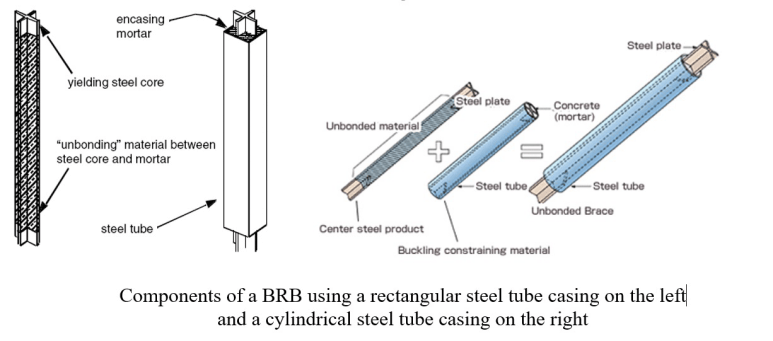

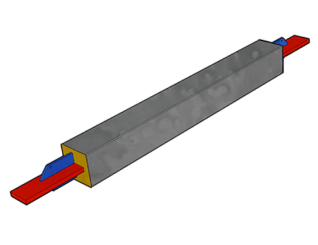

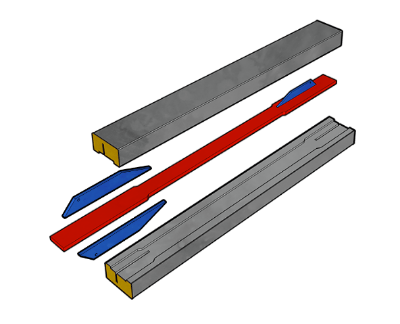

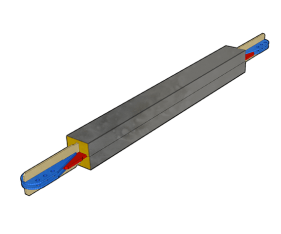

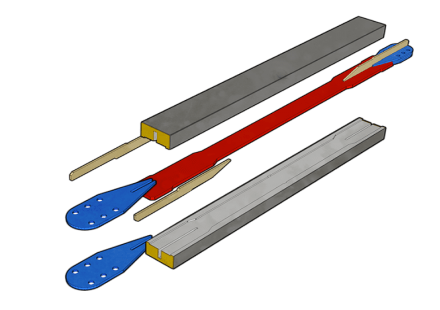

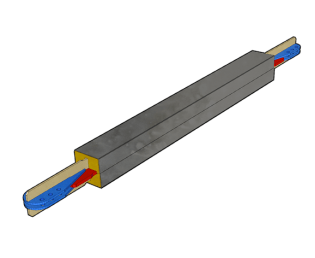

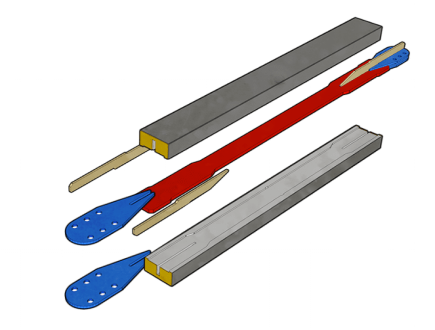

Three major components of a BRB are:

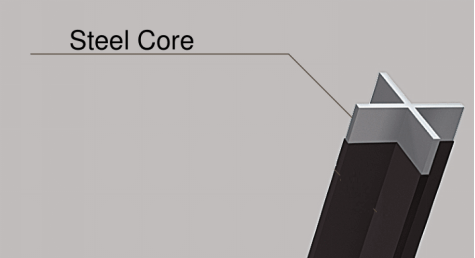

1. Steel core

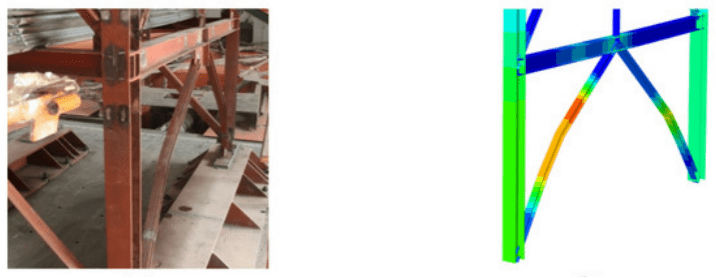

The steel core is designed to resist the full axial force developed in the bracing. Its cross-sectional area can be significantly lower than that of regular braces, since its performance is not limited by buckling. The core consists of a middle length that is designed to yield in elastically in the event of a design-level earthquake and rigid, non-yielding lengths on both ends. Increased cross-sectional area of the non-yielding section ensures that it remains elastic, and thus plasticity is concentrated in the middle part of the steel core. Such configuration provides high confidence in prediction of the element behavior and failure.

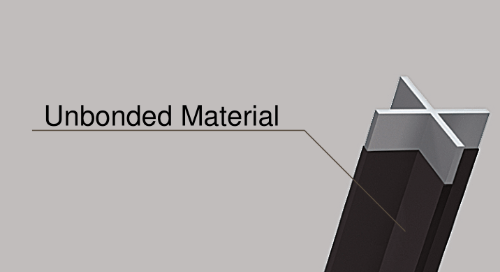

2. Bond-Preventing Layer

The bond-preventing layer decouples the casing from the core. This allows the steel core to resist the full axial force developed in the bracing, as designed.

3. Casing

The casing – through its flexural rigidity – provides the lateral support against flexural buckling of the core. It is typically made of concrete-filled steel tubes. The design criterion for the casing is to provide adequate lateral restraint (i.e. rigidity) against the steel core buckling.

Characteristics of BRB

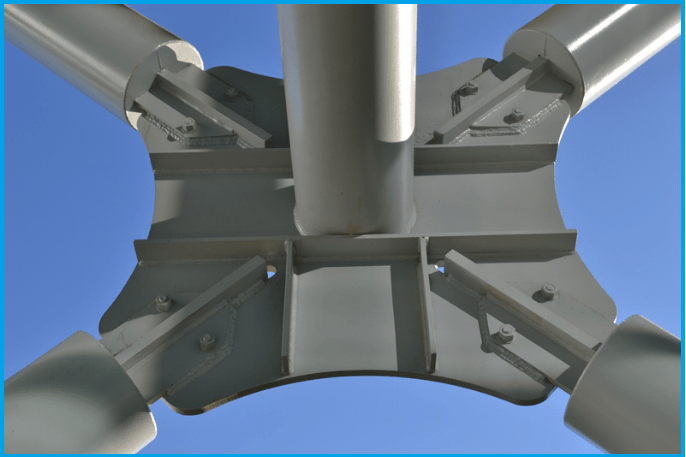

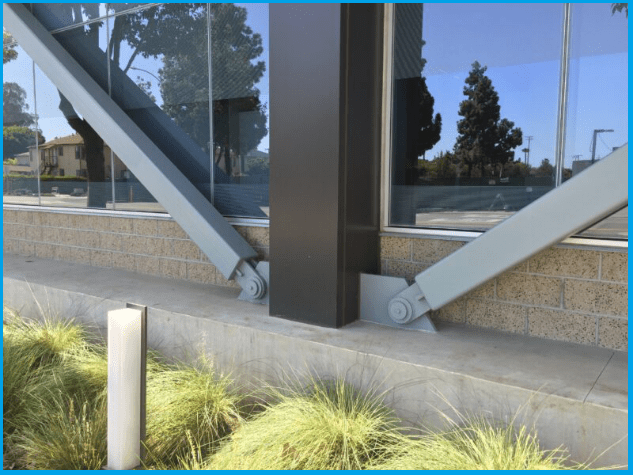

BRB Connection

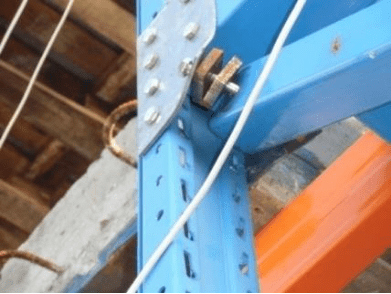

The purpose of buckling-restrained braces is to dissipate lateral forces from columns and beams. Therefore, the connection of the braces to beams and columns can greatly affect the performance of the brace in the case of a seismic event. Typically, the brace is attached to a gusset plate, which in turn is welded to the beam and/or column that the brace will be attached to.

Types of BRB

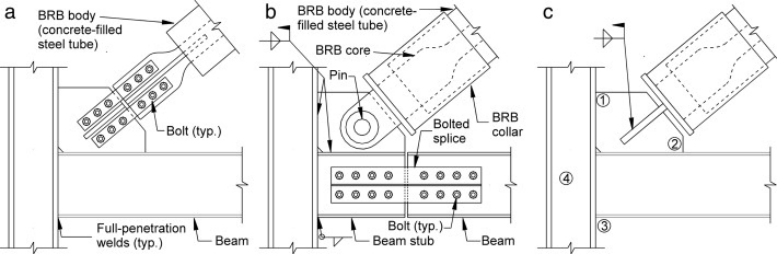

Usually three types of connections are used for BRBs:

The brace is fully welded to the gusset plate in the field. Although this option requires additional man-hours on-site, it can increase the performance of the brace itself by improving the force transfer mechanism, and potentially lead to smaller braces.

Welded BRB Connections on Site

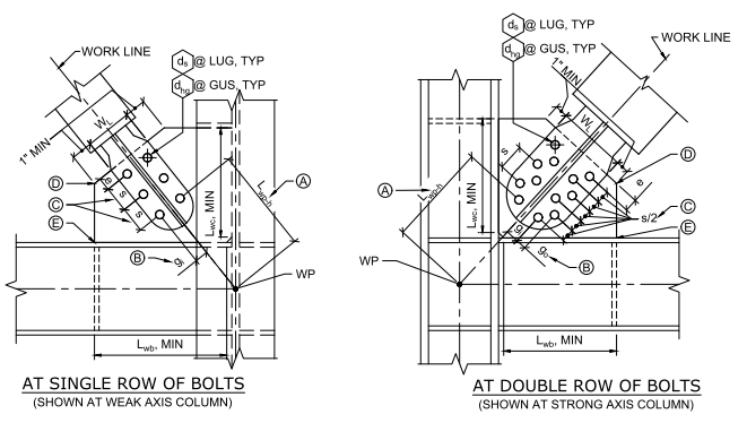

The brace is bolted to the gusset plate in the field.

Bolted BRB Connections on Site

Picture-2.3

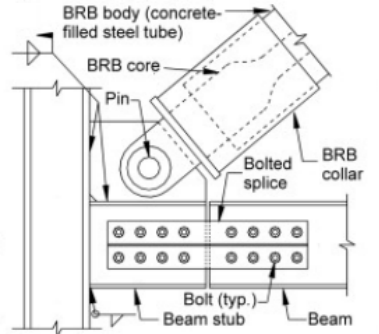

3. Pinned BRB Connection

The brace and gusset plate are both designed to accept a pin, which connects them to each other and allows for free rotation. This can be beneficial to the design engineer if he or she needs to specify a pinned-type connection.

In addition to the connection type, the details of the connection can also affect the transfer of forces into the brace, and thus its ultimate performance. Typically, the brace design firm will specify the proper connection details along with the brace dimensions.

Pinned BRB Connections on Site

Advantages of BRB

Comparative studies, as well as completed construction projects, confirm the advantages of buckling-restrained braced frame (BRBF) systems. BRBF systems can be superior to other common dissipative structures with global respect to cost efficiency for the following reasons:

Buckling-restrained braces have energy dissipative behavior that is much improved from that of Special Concentrically Braced Frames (SCBFs). Also, because their behavior factor is higher than that of most other seismic systems, and the buildings are typically designed with an increased fundamental period, the seismic loads are typically lower. This in turn can lead to a reduction in member (column and beam) sizes, smaller and simpler connections, and smaller foundation demands. Also, BRBs are usually faster to erect than SCBFs, resulting in cost savings to the contractor. Additionally, BRBs can be used in seismic retrofitting. Finally, in the event of an earthquake, since the damage is concentrated over a relatively small area (the brace’s yielding core), post-earthquake investigation and replacement is relatively easy.

An independent study concluded that the use of BRBF systems, in lieu of other earthquake systems, produced a cost per square foot savings of up to $5 per square foot.

Disadvantages of BRB

Buckling restrained braces rely on the ductility of the steel core to dissipate seismic energy. As the steel core yields, the material work-hardens and becomes stiffer. This work hardening can represent increases in the expected force of up to 2x the initial yield force. This increased stiffness decreases the building’s period (negating some of the initial increases) and increases the expected spectral acceleration response requiring stronger foundations and connection strengths.

Buckling restrained braces rely on ductility and generally must be replaced after usage during a major earthquake.

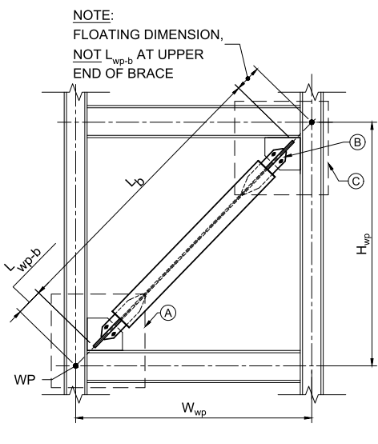

BRB Symbols

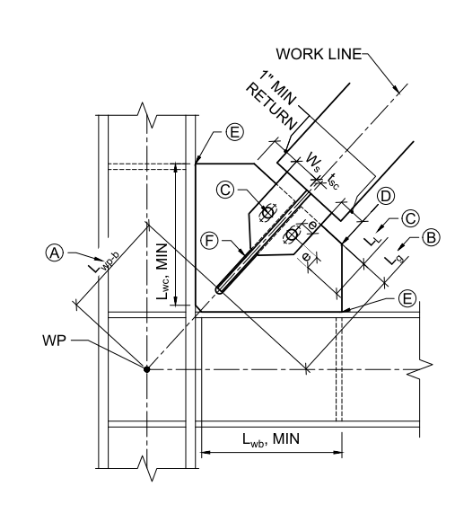

Wwp = Width of frame bay workpoint (WP) to WP

Hwp = Height of frame bay WP to WP

Lb = Length of CB end to end of core

Lwp-b = Length from WP to bottom end only of CB

e = Typical erection bolt edge distance

Dwg = Size of weld for core to gusset

Dwsg = Size of weld for core stiffeners to gusset

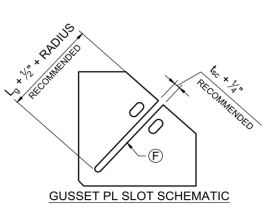

Lg = Length of core lap on gusset

LL = Length of stiffener lap on gusset

Le = Length of core beyond core stiffener

ts = Thickness of core stiffener

Ws = Width of core stiffener

tg = Thickness of gusset

Fy,g&r = Gusset A572 grade

tsc = Thickness of core

db = Diameter of erection bolts

L’ = Length of bolt needed with F436 washer only

La = Suggested Length of bolt to order, detailer to verify

Wb = Minimum size of beam weld

Lwb = Minimum length of beam weld

Wc = Minimum size of column weld

Lwc = Minimum length of column weld

Lgb = Approximate maximum width of gusset rounded up to nearest inch

(At V or Chev, equal to 1/2 gusset width)

Lgc = Approximate maximum height of gusset rounded up to nearest inch

Gusset Overall Layout Procedure

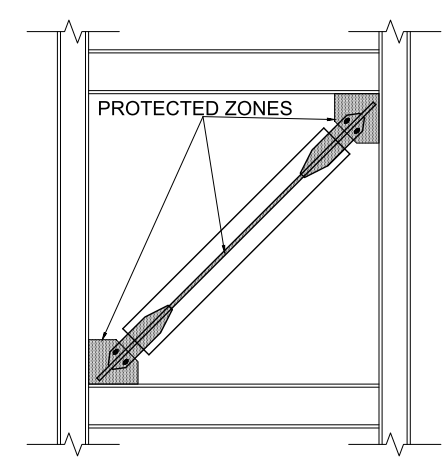

BRB Protected Zones

Design Method and How it Affects the Cost, Weight, and…

The Ultimate Guide to Structural Steel Stairs What are Stairs?…

Structural Bolts Structural bolts play a crucial role in ensuring…

The Ultimate Guide to AESS This guide dives into the…

Steel detailing is a meticulous task that demands high precision….

Understanding how to read and interpret steel detail drawings is…